Consumer electronics

Adhesives for consumer electronics

Innovations in smartphones, tablets, wearables and in the smart home sector are closely linked to innovations in adhesive bonding technology. Adhesives not only facilitate miniaturization, but also increase performance and improve smart device functionality and reliability.

For example, high-tech adhesives are used to bond mini speakers, camera modules and MEMS microphones. They are also used to bond and seal optical, mechanical and electrical sensors.

DELO offers a range of adhesives, potting compounds and encapsulants especially for the consumer electronics sector. The materials are optimized for their application area and stand out with their high resistance to humidity and perspiration. They also satisfy all standard tests customary in the industry such as the drop test or accelerated aging and are designed to enable the highest UPH. Typical product groups for bonding and sealing smart device components are DELO PHOTOBOND, DELO DUALBOND and DELO KATIOBOND.

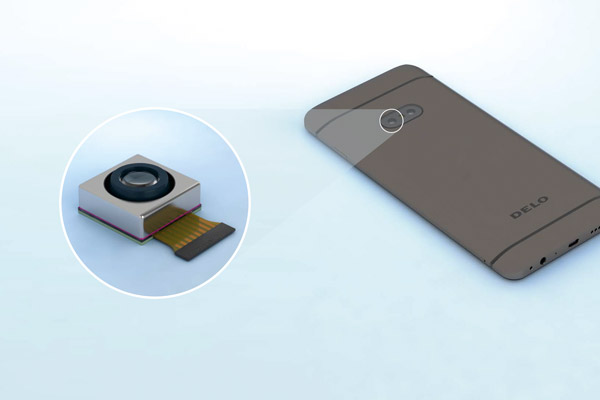

Bonding smartphone cameras or XR-cameras

Smartphones generally have several cameras. Modern camera modules are ultra-compact and contain many tiny components. Various adhesives are required to bond the individual components. DELO has an extensive product portfolio to deliver the optimum solution for each of the more than 30 bonding tasks.

For lens bonding and active alignment processes, for example, DELO has developed special dual-curing products and mCD- &VLT-based adhesives. They can be fixed under light in less than a second, cured at very low temperatures ≥ 60 °C and offer properties such as low outgassing, high temperature stability and humidity resistance. And when it comes to the simultaneous structural bonding and electrical contacting (grounding) of metal components, special isotropic, electrically conductive adhesives from the DELO DUALBOND and DELO MONOPOX series are suitable for this task. They are optimized for low-temperature curing and dispense with soldering processes that can damage temperature-sensitive components.

Typical bonding areas on camera modules

- Housing bonding with active alignment

- Alignment and bonding of several camera modules to one another

- Actuator bonding

- Anchoring

- Grounding

- Filter bonding

New applications / trends

- Moving Iris

- Periscope Camera

Properties of DELO smartphone camera adhesives

- Low outgassing, low shrinkage

- Fixation in < 1 s

- Curing at low temperatures ≥ 60 °C

- Adjusted flow behavior

- Good adhesion to substrates such as FR4, LCP and ceramic

- High drop test resistance

- Solvent-free

- Halogen-free according to IEC 612409-2-21

- PFAS-free

Adhesives for large and small speakers

Whether in a smartphone or a smart home speaker: speaker modules consist of a multitude of components that influence the sound quality. So does the adhesive that joins the components.

DELO has developed special products for the loudspeaker sector that contribute to improving the acoustics with their coordinated properties. The adhesives meet the technical requirements for high power density as well as high temperature resistance and durability, while at the same time enabling fast and fully automated production.

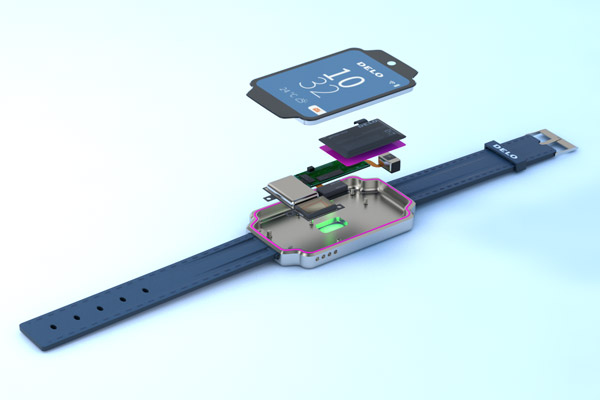

Bonding sensors in smartphones and similar devices

Smartphones and smartwatches contain a formidable number of sensors. These include proximity, ambient light and acceleration sensors as well as image and MEMS sensors.

In order to reliably bond and permanently protect the sensors, DELO offers a variety of adhesives and sealants that enable both fast prefixation (DELO DUALBOND) and are optimized for low temperature curing (DELO MONOPOX). The DELO materials stand out with their high adhesion and pass tests such as MSL1 and thermal shock storage. In addition to the mechanical properties, the electrical / dielectric properties can also be adapted to the relevant application up to high frequency ranges.

Furthermore, the dispensing and flow properties of the DELO adhesives can be adjusted to achieve fast processes. Due to their suitability for screen and stencil printing processes, the materials also enable the production of many miniature assemblies at wafer, panel or strip level.

Properties

- High temperature resistance

- Low coefficient of expansion

- Excellent flow behavior

- High reliability

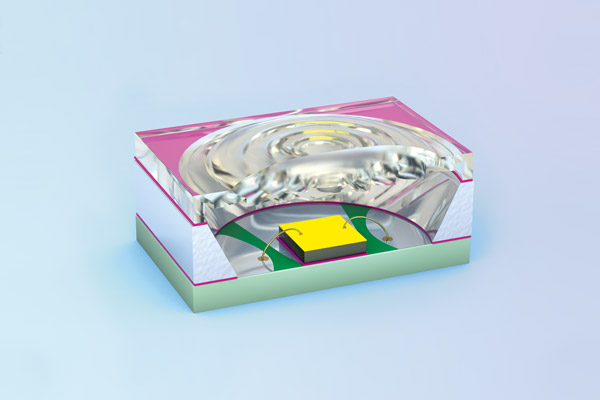

DELO adhesives for LED packaging

LEDs are widely used due to their small form factor and high efficiency – as ambient lights or for sensors, for instance. They enable increasing miniaturization as well as design flexibility and versatile applications.

Functional adhesives play a key role in the production of LED packages. They ensure brilliant, homogeneous diode illumination and fast production. DELO has developed a host of suitable products for both first- and second-level packaging. In first-level packaging, the adhesives are applied in the immediate vicinity of the LED semiconductor. In second-level packaging, the adhesives are used to join lenses, cover disks and housings that are used around the LED module.

DELO's adhesive portfolio for optoelectronics includes transparent and low-outgassing, tension-equalizing and electrically conductive adhesives, and die attach to structural bonding. Optical coatings with customized properties regarding transmission, reflection and absorption, as well as encapsulants to protect sensor packages, are also offered by DELO. Users can select products with different curing mechanisms depending on the component geometry or substrate combination.

All DELO functional adhesives and sealants in the DELO PHOTOBOND, DELO DUALBOND, and DELO KATIOBOND series are particularly suitable for highly automated, high-speed processes with high outputs.

Properties of adhesives for LEDs

- Low-outgassing

- Very low shrinkage

- Optically clear

- Yellowing-resistant

- Reflow-resistant

Adhesives for displays of all sizes

Displays are everywhere. Whether on smartwatches, smartphones, or tablets – suitable solutions are needed to reliably bond the displays to their housings or to permanently seal and mechanically protect them.

Applications

- Smartphones

- Tablets/laptops

- Wearables

- TV

- Camera displays

- Navigation and entertainment systems

- Machine and system displays

- Industrial PCs

- Displays in household appliances (e.g. kitchen appliances, washing machine)

- Display protection glass

- OLED edge coating

When integrating displays into assemblies, the most important thing is to create a tension-free and reliable connection between the display glass and the frame as well as between the different materials of retainers, housings, and for active components. Something else to consider is the size of the assemblies, which often requires the use of room-temperature-curing adhesives.

DELO has developed special adhesives with optimum properties that allow for fast production processes. This range includes DELO PHOTOBOND adhesives that can be preactivated with light and then cured by humidity, thus enabling “curing on demand”. Even opaque components can be bonded quickly and reliably with these products.

DELO’s liquid pressure-sensitive adhesives offer another way of bonding display frames. They combine the properties of industrial tapes with the easy and automated processing of liquid adhesives.

Typical bonding tasks

- Structural bonding of displays to frames and housings

- Sealing of housings

- Bonding of operating elements to display protection glass

- Bonding of various components such as COG/COF or flex conductors to displays

- Bonding of functional components to the display structure (haptic feedback)

- Bonding of various components in head-up displays

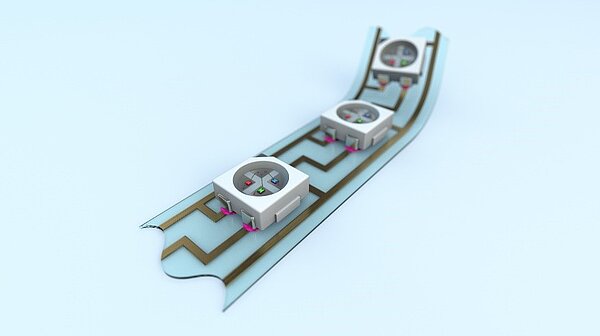

Flexible electronics

Flexible electronics offer enormous advantages over conventional electronics on classic PCBs in terms of design freedom and the associated weight and cost reductions. Particularly in the case of flexible hybrid electronics (FHE), whose high functionality is largely determined by the integration of rigid SMD components, adhesives can have many applications.

Complex circuits are applied to flexible and particularly elastic carrier foils by printing with conductive silver inks. These substrates are usually very temperature-sensitive and, therefore, difficult to access for soldering processes. In addition, subsequent use creates high mechanical demands for the substrate/SMD component interface.

DELO offers competent solutions for electrical bonding as well as structural bonding of electrical components (SMD) on flexible substrates.

Depending on the component size and process, electrical connections can be made with isotropic conductive adhesives (ICA) or anisotropic conductive adhesives (ACA). Structural reinforcement via non-conductive adhesives (NCA) is an established technique, especially when combined with ICAs, to ensure reliable long-term functionality.

When combined, DELO DUALBOND® IC343 and DELO DUALBOND® AD345 are already successfully used in a large number of applications with flexible electronics, characterized by the following properties:

- Fast curing at low temperatures

- High electrical conductivity

- Matched flexibility and mechanical properties

- High-precision wet-on-wet microdispensing (jetting)

- Strong adhesion to a wide range of substrates

- High compatibility with polyurethane-based silver inks

- Optional light fixation

Brochures for download

A digital knowledge package

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request

Do you have any questions?

Get in touch with us!

Technical consulting, sample and data sheet inquiries:

+49 8193 9900 - 9611

General & others:

+49 8193 9900 - 0