DELO-ACTIVIS 600

![[Translate to English (US):] [Translate to English (US):]](/fileadmin/_processed_/2/9/csm_products_equipment_delo-activis_600_applications_4059830b74.jpg)

Dispensing and preactivation in one step

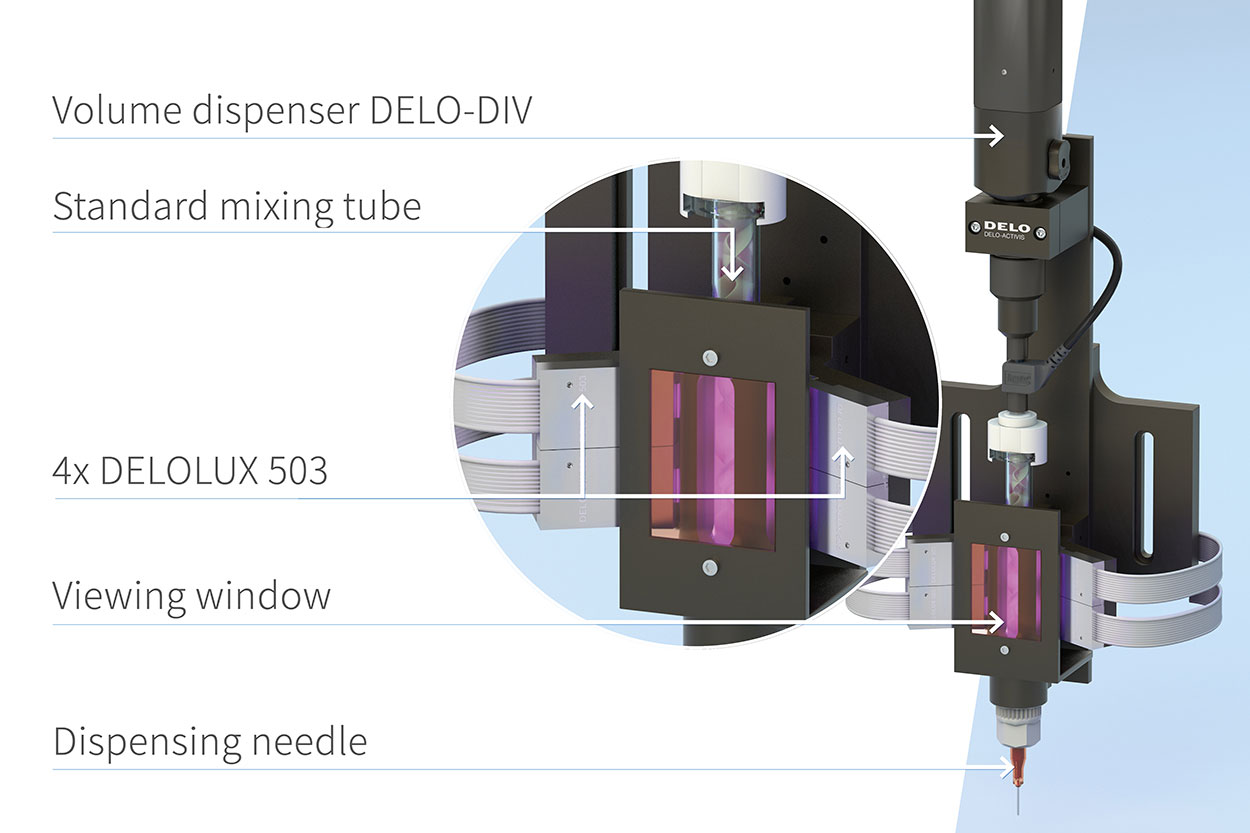

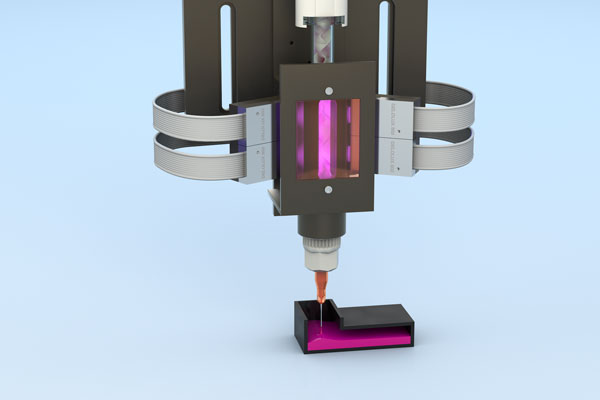

The DELO-ACTIVIS 600 dispensing unit is an innovative system consisting of a dispensing and irradiation unit. It was specially developed for the process of flow activation and enables the dispensing and preactivation of high-tech adhesives in one process step. Dispensing is volumetric, whereby flow rate and quantity can be defined according to the process requirements. Four powerful DELOLUX 503 UV lamps are integrated in the system to preactivate the adhesives. They ensure that the curing process already starts during dispensing.

DELO-ACTIVIS 600 is a space-saving solution that can be integrated into existing systems or used as a stand-alone unit. It scores particularly well when bonding and potting electronic components such as sensors, pins or microelectronic components. The device in combination with the new process technology enables energy- and cost-efficient bonding processes.

The products of the DELO KATIOBOND FA series are suitable adhesives. These are light-curing, available with different mechanical properties and are characterized by good temperature and media resistance in the cured state.

- Savings in process costs and CO2 emissions

- Suitable for complex geometries and opaque materials

- Direct further processing of the components through additional light fixation

Further information on the process can be found in our white paper "Two in one: Activation on the flow"

as well as in the TECH TALK - Webinar.

Brochures of DELO-ACTIVIS 600

THE FOLLOWING PRODUCTS COULD BE INTERESTING

Do you need assistance with your application?

Our experts will be pleased to offer advice and assistance.

Do you have questions about a specific application? If so, please use our project form.

The more detailed the description, the faster you will receive your optimum product sample.

![[Translate to English (US):] [Translate to English (US):]](/fileadmin/user_upload/images/content/products/equipment/dispensing_systems/products_equipment_delo-activis_600_applications.jpg)