Lampen und Steuerungsgeräte

Bild

Produkt

Eigenschaften

Downloads

Broschüren

DELOLUX pilot S | Serie

Broschüren

LED-Steuergeräte

DELOLUX pilot AxT, DELOLUX pilot Axi / PROFINET,

DELOLUX pilot S4T, DELOLUX pilot S4i

Broschüren

DELOLUX pilot A | Serie

Broschüren

LED-Steuergeräte

DELOLUX pilot AxT, DELOLUX pilot Axi / PROFINET,

DELOLUX pilot S4T, DELOLUX pilot S4i

Broschüren

DELOLUXcontrol

Broschüren

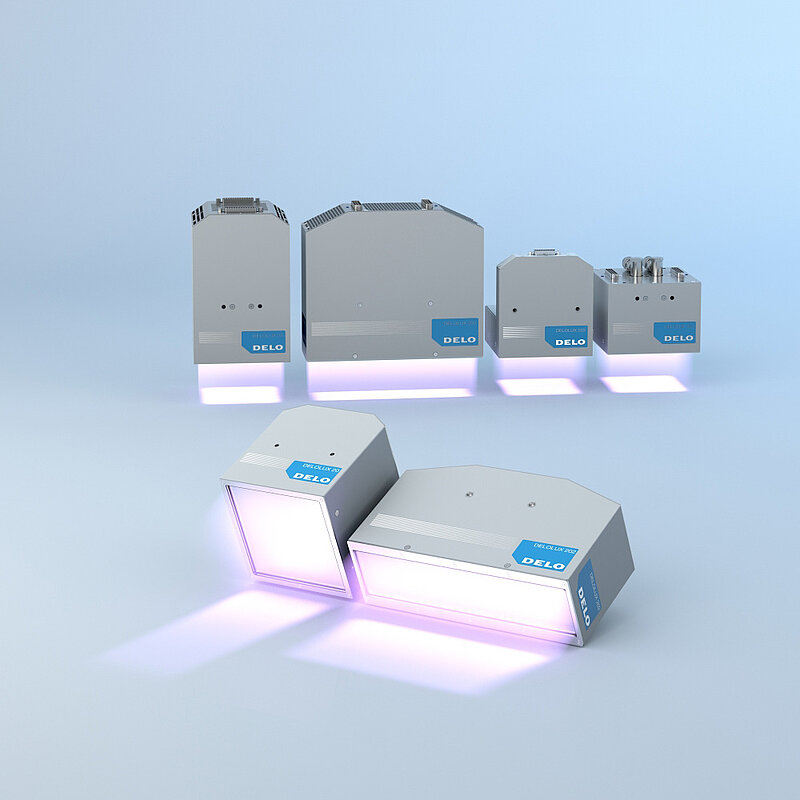

DELOLUX 80

Broschüren

DELOLUX 80

LED-Aushärtungslampe

LED-Aushärtungslampen

DELOLUX 50 | 505 | 80

Broschüren

DELOLUX 20 | 202 | 203 | 204

Broschüren

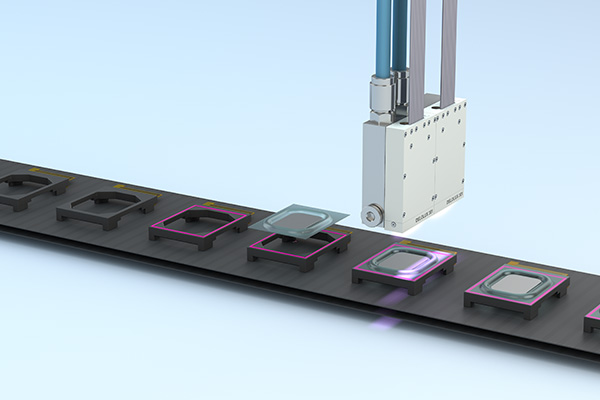

LED-Aushärtungslampen

DELOLUX 20 | 202 | 203

DELOLUX 20 und DELOLUX 202

LED-Flächenlampen

optionale Wasserkühlung

Hohe Flexibilität

Modularer Aufbau

Broschüren

DELOLUX 301

Broschüren

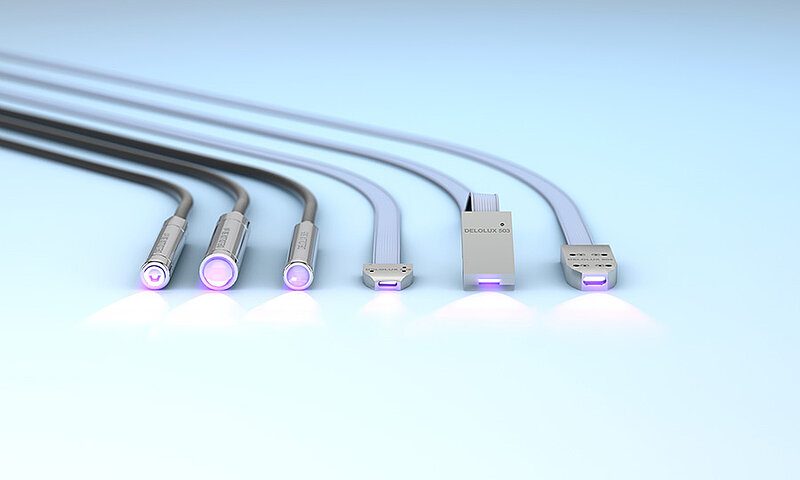

DELOLUX 50 | 502 | 503 | 504 | 505

Broschüren

LED-Aushärtungslampen

DELOLUX 50 | 505 | 80

LED-Aushärtungslampen

DELOLUX 502 | 503 | 504