Particularly resistant epoxy resin adhesives with special hardeners are used where bonded or encapsulated components are exposed to extreme temperatures and aggressive chemicals. However, only heat-curing variants have been available up to now.

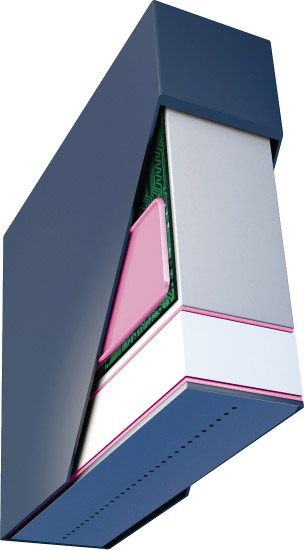

By contrast, the light curing of the newly developed product offers greater bonding accuracy, a defined fillet, and easier handling of the cured components. What's more, in the case of glob top encapsulation, it forms a skin and can "freeze" its shape, so does not flow away during heat curing. This means that a defined glob top encapsulation is possible even if miniaturization makes space tight on the circuit board, which saves one process step compared to the alternative Dam & Fill method.

Top Performance Even in Aggressive Media Like Oil or Printing Inks

In a two-stage curing process, the adhesive is first light-cured in 1 - 5 seconds, depending on intensity, and achieves a die shear strength of more than 1 N on the FR4 circuit board material. Heat curing is required, for example 30 minutes at +150 °C, after which the full strength of 50 MPa on FR4 is attained.

The dual-curing product has universal adhesion and is available in viscosities for bonding applications as well as for encapsulation. Both variants are easy to work with thanks to their thixotropic flow characteristics. Their temperature range of use extends from - 65 °C to +180 °C. For even higher thermal requirements, DELO has recently introduced high-temperature adhesives to the market, which are temperature-resistant up to +250 °C.

Despite its hybrid nature, the epoxy resin is highly resistant to chemicals. Even after 500 hours stored in aggressive media, like transmission fluid, gasoline, or methanol, there is hardly any effect on its mechanical properties. The product also exhibits good resistance to printing inks, which attack most adhesives. It is therefore particularly suitable for adhesive applications in the print head that require highly accurate positioning.