Structural bonding

Structural adhesives – high-strength connections with DELO adhesives

DELO structural adhesives ensure permanent joints between materials such as metal, plastic or composites. Their high-strength adhesives are used primarily in household appliances, cars, and even aircraft. The DELO portfolio offers solutions for diverse requirements ranging from curing within seconds for short cycle times to long processing periods for batch processes.

- Structural adhesives for high-strength connections

- High aging resistance to temperature and media

- Extensive portfolio for different production processes

- Advice on the adhesive-friendly design of bonded joints

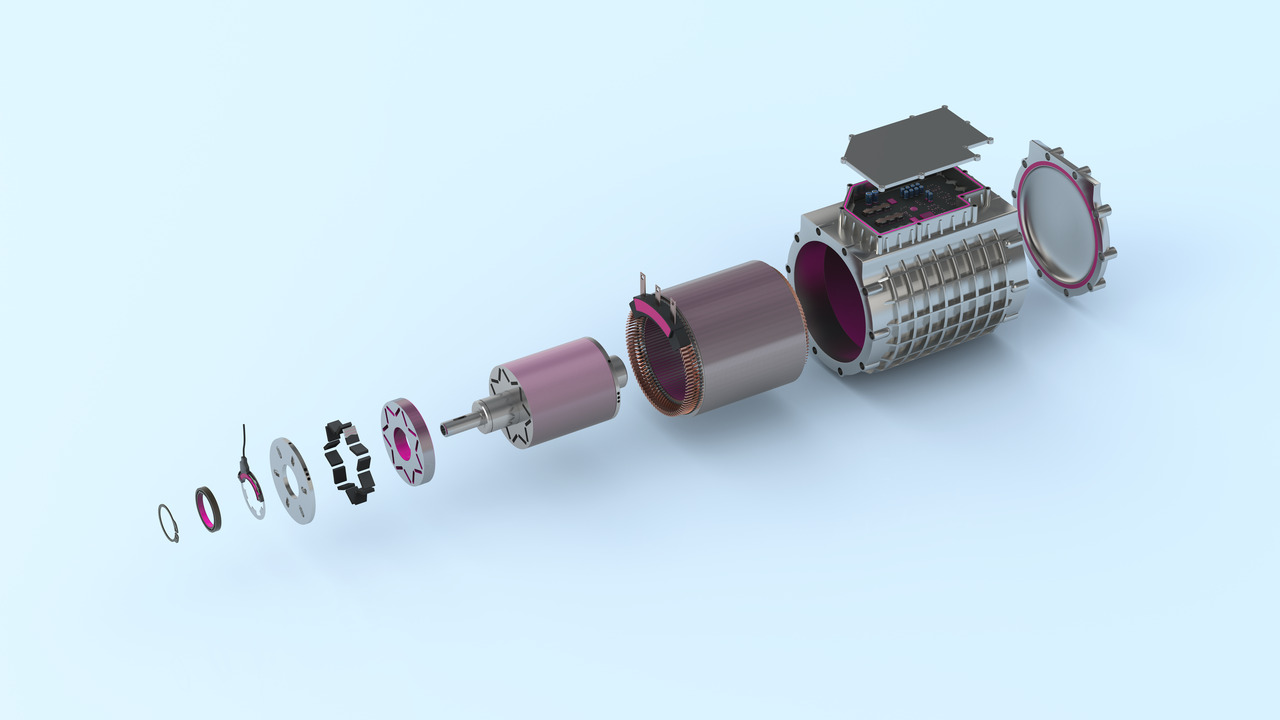

Automotive adhesives for long-lasting strength

Structural adhesives are widely used for bonding tasks in the automotive industry, from car bodies to electric motor magnets and display frames. Besides high temperature and media resistance, these applications primarily demand very good strength throughout the vehicle's life cycle. DELO's structural adhesives meet the requirements of OEMs and suppliers and also ensure greater passenger safety thanks to the tension-equalizing properties of safety-relevant components.

- Fulfill automotive-relevant test requirements

- Enable lightweight design through multi-material bonding

- Energy-saving curing with UV light

Design freedom with bonded fastening elements

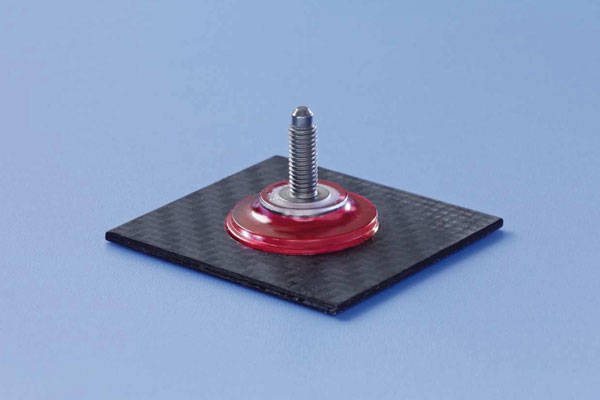

DELO and Böllhoff have developed the so-called ONSERT® process. It unifies the advantages of bonding and screwing and thus creates new possibilities for joining lightweight structures.

ONSERT® is a system in which transparent plastic fasteners, with or without metal thread reinforcement, are fixed by means of light-curing adhesive. The bonded joint can withstand loads immediately thanks to light curing within seconds.

- Connection can withstand loads immediately after curing within seconds

- Ideal for the non-destructive bonding of fiber composite materials

- For common clip materials such as polyamide (PA), polycarbonate (PC), or polybutylene terephthalate (PBT)

Aerospace – adhesives enable lightweight design

In addition to the automotive industry, lightweight design plays the key role in the aviation industry, especially in aircraft interiors. Adhesives bond materials reliably without increasing the overall weight unnecessarily. Bonding is therefore the ideal joining method for achieving lightweight aircraft design. Adhesives can be found everywhere in aircraft interiors: In lighting elements, displays, air conditioning systems, seats, fastening elements, cockpit doors and in the electronics. In addition to low density, high temperature and flame protection requirements are particularly important.

- Flame protection FST available for various products

- Very good temperature stability

- Qualified and approved according to AIMS 10-04-001 (product-dependent)

Brochures for download

Knowledge in online format

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request