Joint tests of Xaar and DELO show that even optical materials with viscosities of 250 mPa·s can be inkjet-printed. This offers benefits for several industries, particularly for optical elements in consumer electronics and automotive applications.

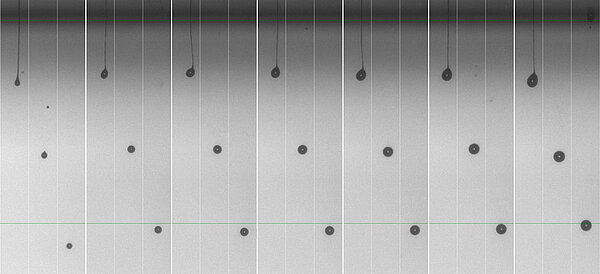

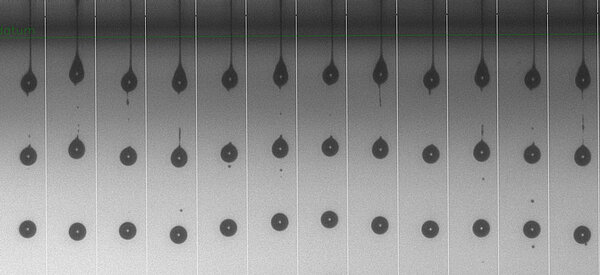

Most inkjet printheads are capable of jetting materials with a viscosity range of 10-25 mPa·s. Xaar’s unique ink recirculation TF Technology allows advanced optical materials, with significantly higher viscosities, to be successfully jetted. This is achieved by heating fluids with a viscosity of 250 mPa·s at room temperature to 43 °C, reducing the viscosity to 63.5 mPa·s, and enabling them to be effectively ejected with Xaar’s printheads.

Having this capability provides manufacturers of optical elements with more design flexibility. It also offers an alternative to imprint lithography as they can create single (micro) lenses or 3D-print whole micro lens arrays.

Additionally, the precise placement of tiny droplets, a few picolitres in size, makes inkjet-printing ideal for coating and protecting thin layers to achieve optical correction. It has proven to be a viable alternative to spin coating and other dispensing methods by significantly reduced material waste up to 80 percent.

Optical materials based on UV-curing polymers instead of glass or injection-molded plastics have become increasingly widespread in recent years. They are used as lenses for applications like flashlights, time-of-flight-sensors or diffractive optical elements (DOEs) for structured light emitters and miniature cameras.

DELO provides fast UV curing materials with excellent optical properties such as a matched refractive index, high transmission and non-yellowing. They are all solvent-free and provide adjusted mechanical functions and stability, as well as good adhesion and application on various substrates.

Xaar’s unique recirculating TF Technology ensures unbeatable performance and excellent reliability without any nozzle blocking from large particles due to the fluid being kept in constant motion. It also offers increased functional capabilities for materials developers, including flexibility, low migration and increased gamut.