DELO, one of the world’s leading manufacturers of industrial adhesives for automotive, consumer and industrial electronics applications, recently developed an innovative process technology combining adhesive dispensing and preactivation in a single process step. Activation on the flow provides users with new options for designing their products and processes while reducing costs and CO2 emissions.

Ideal for bonding and encapsulating temperature-sensitive electronic components, this new technology offers an alternative to bonding processes previously used in industry.

Unique Technology

The adhesive is already irradiated during the dispensing process, which starts the curing reaction even before the adhesive meets the component. After the combined process step, the components can be joined. Another unique feature of the technology is that the exposed adhesive areas can be additionally irradiated and fixed after joining. This provides immediate initial strength, preventing the adhesive from flowing out and the components from slipping, while allowing them to be further processed right away. The adhesive cures reliably to final strength whether or not there is additional light fixation. No additional process steps are needed, even in undercuts and shadowed areas.

The one-component adhesives, developed specifically for activation on the flow, are based on epoxy resin. The patented DELO KATIOBOND FA adhesives contain two different initiators that react to different wavelengths and initiate curing. This dual-initiator system is what makes the optional light fixation step possible. The adhesives are available with different mechanical properties and are highly resistant to media and temperature in the cured state.

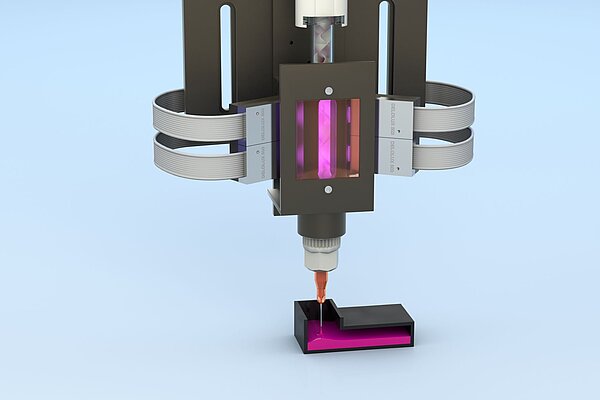

Dispensing and Irradiation

DELO has also developed the appropriate device DELO-ACTIVIS 600. It is made up of two subunits, one for dispensing and one for irradiation. Dispensing is done on a volumetric basis, with flow rate and quantity defined according to process requirements. As the one-component adhesive passes through the mixing tube, it is irradiated by integrated DELOLUX 503 curing lamps. The mixing coil ensures uniform activation of the entire adhesive volume. DELO-ACTIVIS 600 can be used as a stand-alone device or integrated into existing production systems.

“With activation on the flow, we have developed a complete system combining process technology, adhesive and device, which enables innovations on the customer side,” said Dr. Karl Bitzer, Head of Product Management at DELO. “The various customizable parameters open up completely new possibilities in terms of component design, efficient processes, and CO2 reduction.”

Activation on the flow is well-suited for bonding and encapsulating temperature-sensitive components. For example, sensors or connectors can be bonded in a ‘gentle’ way and with low stress using dual-initiator adhesives. None of the components need to be transmissive to light, and the adhesive cures reliably even in complex geometries.

This new technology can replace various bonding processes widely used in the industry. It is an efficient and environmentally friendly alternative for heat-curing, room-temperature-curing, or dual-curing processes. It helps to overcome previous limitations and creates room for innovation.