Manufacturing

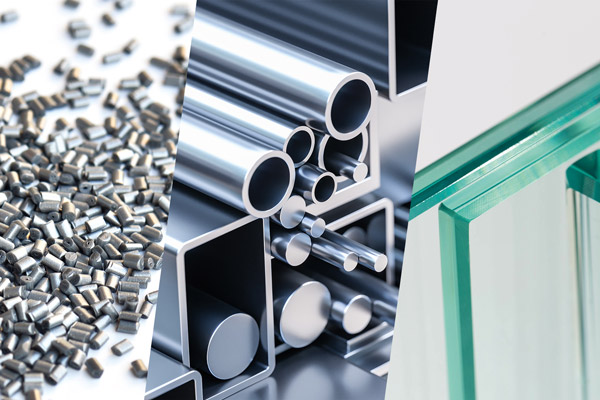

DELO adhesives are optimized for fast, accurate, and fully automated production, ensuring maximum manufacturing efficiency. The majority of our more than 400 products have a light or dual curing mechanism, enabling curing within seconds, short cycle times and direct continuation of the process. For a wide variety of materials, such as plastics, metals or glass, our high-tech adhesives enable both efficient processes and high strength throughout the entire life cycle. Various processes are suitable for dispensing – including needle dispensing, jetting, screen and stencil printing. Functional 3D printing components can also be produced with DELO adhesives.

A digital knowledge package

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request

Do you have any questions?

Get in touch with us!

Technical consulting, sample and data sheet inquiries:

+49 8193 9900 - 9611

General & others:

+49 8193 9900 - 0