Electronics

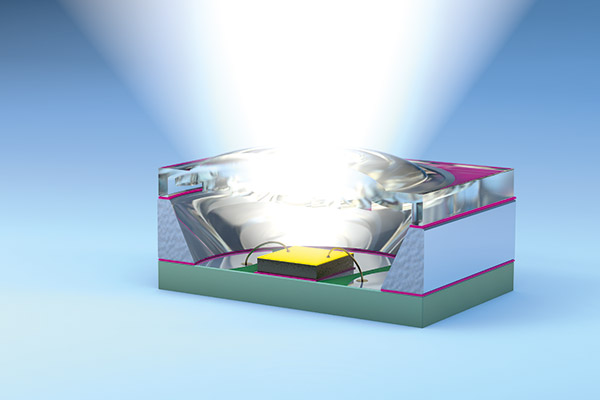

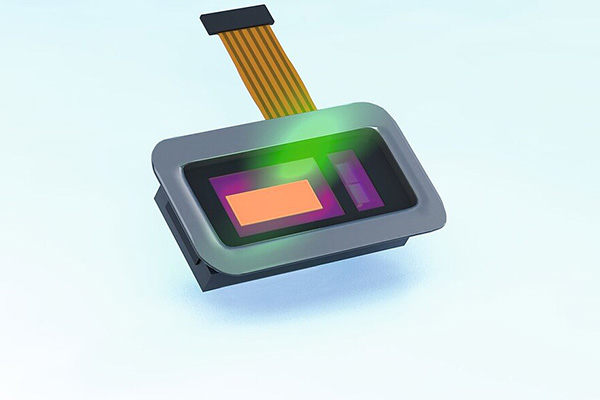

High-tech components, such as camera modules, sensors, RFID tags or optoelectronic elements can be manufactured more efficiently using adhesives. The adhesive makes an essential contribution to the function and durability of the bonded components and enables the size of the assembly to be reduced.

DELO specializes in the development and production of bonding solutions that meet the stringent requirements of the electronics sector. With our adhesives for electronic and optoelectronic components, we are constantly pushing the boundaries of what is technically feasible to strengthen the innovative power of our customers. Our portfolio includes multifunctional adhesives that perform other functions in addition to bonding – for example, adhesives that are transparent to certain wavelengths, electrically conductive die attach adhesives or thermally conductive potting compounds. All products allow fast production processes through their light or dual curing mechanism.

A digital knowledge package

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request

Do you have any questions?

Get in touch with us!

Technical consulting, sample and data sheet inquiries:

+49 8193 9900 - 9611

General & others:

+49 8193 9900 - 0