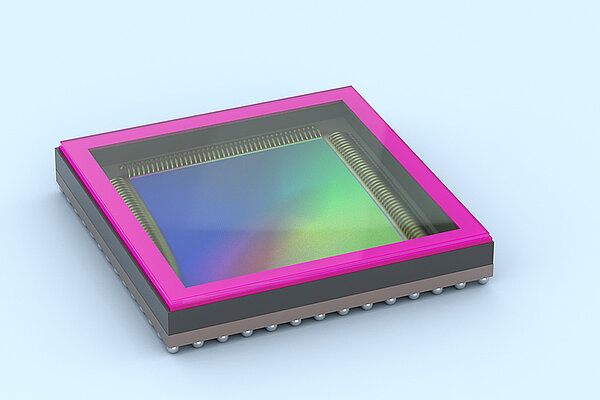

Semiconductors

High-performance adhesives for semiconductors

Adhesives are key components in semiconductor-based devices. DELO semiconductor adhesives are used to bond, contact and encapsulate chips and other SMD components on printed circuit boards. From RFID labels, MEMS sensors to optical components – DELO semiconductor adhesives are used wherever short cycle times and maximum precision are demanded. DELO has also developed special products for the advanced packaging industry. These help increase package performance.

Properties of DELO semiconductor adhesives

- High UPH possible with UV- and heat-curing solutions

- Very good adhesion to many substrates

- Solderless connection

- Adjusted flow behavior

- High temperature stability up to +260 °C

- High ion purity, halogen-free

- JEDEC MSL 1-approved products

- Optimized products for different chip sizes

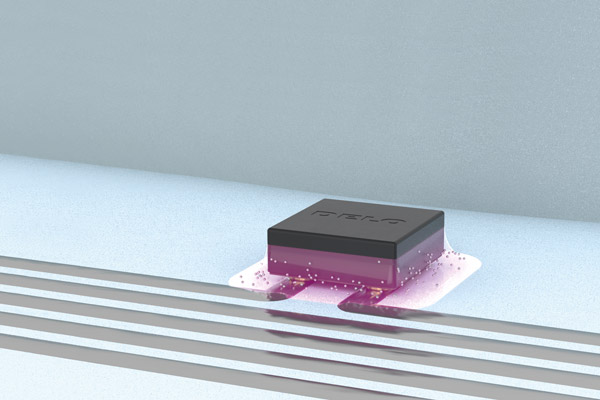

Adhesive solutions for advanced packaging

No mega trend, be it 5G, IoT or AI, can do without high-performance microelectronics and new production methods such as wafer-level packaging (WLP) or fan-out wafer-level packaging (FOWLP). Miniaturization advances and improvements in component functionality are closely linked to the targeted optimization of the properties of the materials used.

DELO develops tailored functional materials optimized for different applications such as die attach, underfilling, cap bonding and encapsulation. The materials are used to bond individual components, protect components, reinforce solder joints (e.g. as Edgebond or Cornerfill) and to produce precise 3D structures. They are used in MEMS sensors, for example. DELO materials therefore enable new and more efficient production processes (through temporary bonding, debonding, reworkability, etc.) and are optimally suited for fully automated series production. They can be applied by screen printing, stencil printing and jetting.

Thanks to the targeted optimization of specific properties, DELO materials help improve assembly performance.

Properties / strengths of DELO products

- MSL1 resistance in the package

- Fast curing

- Tension-equalizing for minimum warpage

- Customized material properties (mechanical / optical / electrical)

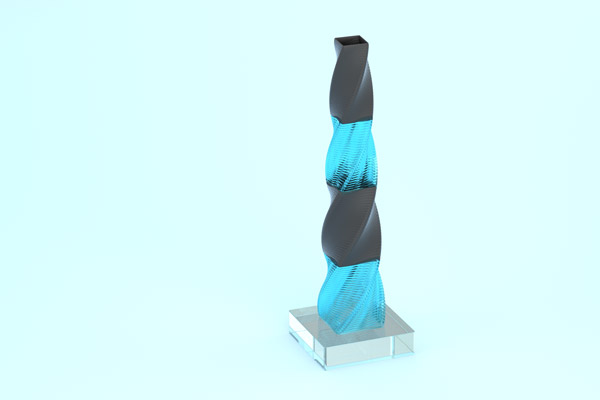

Industrial 3D printing: Functional materials for liquid additive manufacturing

Exciting opportunities for the semiconductor industry are also offered by functional materials developed specially by DELO for industrial 3D printing.

Bonding of RFID chips

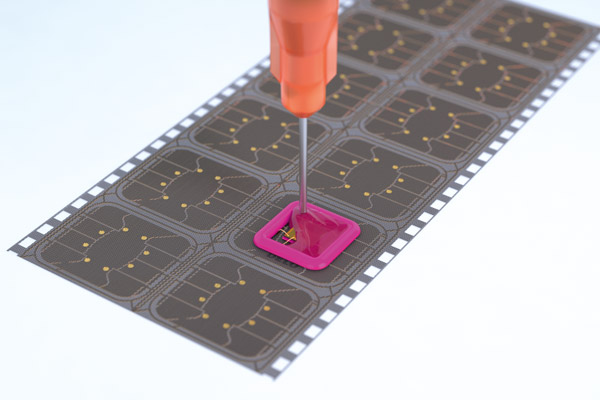

From product packaging and ski passes to RFID transponders: Reliable radio tag function hinges on the connection between the semiconductor chip and the antenna. Semiconductor adhesives play an important functional role. They fix the tiny chips onto the antenna and in most cases also contact them electrically.

DELO is the world's leading manufacturer of RFID adhesive solutions. Around four out of five RFID labels contain a drop of DELO adhesive. Depending on the process, anisotropic conductive (ACA) or non-conductive (NCA) adhesives are used to bond the chips. Specially developed for LF, HF and UHF antennas, DELO's epoxy resins satisfy the high requirements demanded of strength, temperature and humidity resistance, and ensure fast processes. Adhesive and machine integrators aim for an output of 100,000 RFID labels per hour.

In addition to reliable adhesives for RFID labels, DELO offers comprehensive support to ensure that the system comprising adhesive, chip, substrate and equipment is optimally and reproducibly matched. DELO works closely with many machine integrators to ensure this.

Properties / strengths of DELO products

- Anisotropic conductive and non-conductive adhesives available

- Very good adhesion to various substrates

- Humidity-resistant

- Very fast curing (< 1 second), easy to process

- Designed for common processes

such as heat pulse, thermode curing, and flip-chip

Encapsulants to protect smart card chips

DELO offers an extensive range of products for smart card modules that covers all requirements necessary for the bonding and long-term protection of chips. It includes various die attach adhesives and encapsulants that can be used as dam & fill or glob top. The DELO portfolio also includes special conductive adhesives for flip-chip process-based production. In line with the relevant requirement profile, products satisfy all demands from tension equalization to hardness and very high strengths.

Properties / strengths of DELO products

- Anisotropic conductive and non-conductive adhesives available

- Light- and heat-curing dam & fill and glob top encapsulants available

- Flip-chip bonding

Brochure for download

A digital knowledge package

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request

Do you have any questions?

Get in touch with us!

Technical consulting, sample and data sheet inquiries:

+49 8193 9900 - 9611

General & others:

+49 8193 9900 - 0