Fast, Faster, the Fastest – Very Low Temperature Curing

The low curing temperature of these new adhesives reduces the thermal stress between the materials, thus limiting the stress on the component. In addition to that, they allow processing of temperature-sensitive substrates without difficulty: higher temperatures would only damage the sensitive components.

For purely low-temperature-curing DELO MONOPOX adhesives, it only takes 30 minutes and a temperature of +60 °C to achieve their final strength. This makes them the fastest of their kind. So far, standard products have generally taken 90 minutes at the same temperature to achieve full strength. And still they are able to maintain their favorable properties such as their good adhesion to plastics like LCP, PA, and PPS or their flexibility on the component.

Dual-Curing Adhesives – Full Strength at Only +60 °C.

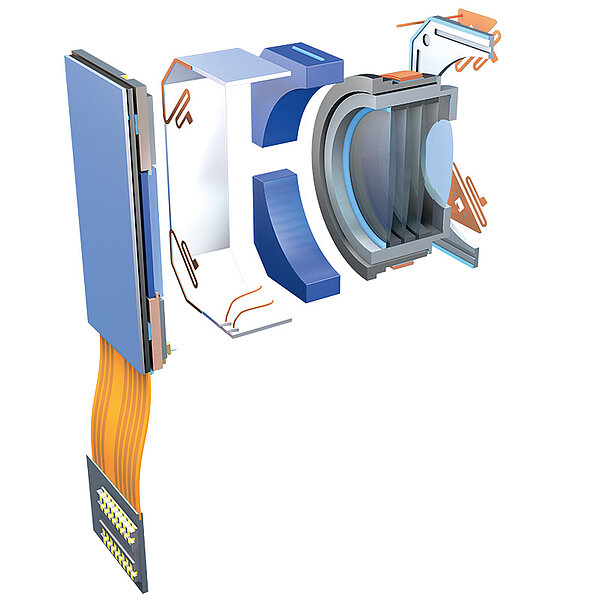

DELO offers DELO DUALBOND adhesives that reach full strength at only +60 °C after prefixation by light. The range is completed by DELO MONOPOX adhesives curing in a single step at low temperatures, three times faster than previous products. These epoxy resin-based adhesives are mainly used in electronics.

The dual-curing adhesives can be prefixed after only half a second of exposure to light. Prefixing is particularly advantageous in the case of production lines, since, after dispensing and fixation, the component will be directly transferred to the next step of the process chain. This guarantees reproducibility and fast production, avoiding incidents like the slipping of individual components. Products of the DELO DUALBOND family also feature excellent adhesion to LCP and allow adjustment of the adhesive properties ranging from flexible to hard (elongation at tear up to 70 %).