Additional benefits of dual curing

Strength and tightness even in shadowed areas Full curing prevents corrosion High bonding accuracy also possible for high-reliability products No further process step necessary in some cases

Benefits of light curing

Fast curing, short cycle times High in-line process control possible Easy plant engineering Easy automation Easy processing

No musts, anything goes

Dual-curing adhesives offer the benefits of light-curing systems without compromising on reliability, bond strength and processing quality. They also ensure that the adhesive in the finished product is fully cured and permit maximum bonding precision in complex modules. They offer a high degree of flexibility in production and allow users more freedom in the development of their production processes.

Most manufacturing companies prefer light-curing adhesives to achieve high productivity levels. However, use of these systems is subject to limitations. So in recent years DELO has focused on pushing these limits further by developing several dual-curing DELO DUALBOND products.

In vast number of industries, including automotive, electronics and mechanical engineering, bonding has become more important due to light-weight construction, miniaturization and multi-material design. Adhesives are also being used more and more as sealants to protect components from environmental influences.

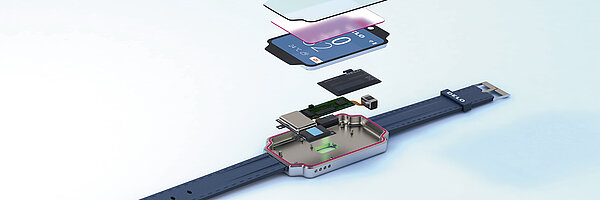

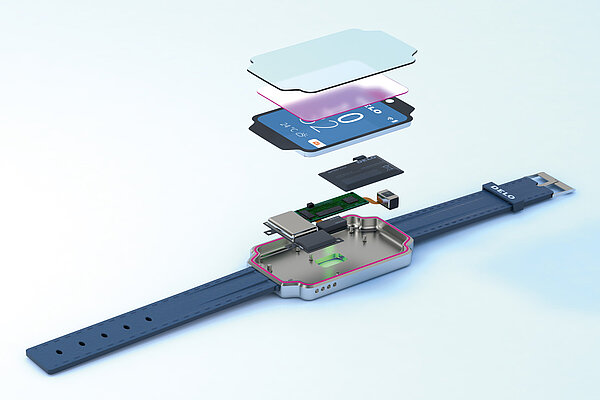

Companies producing mass goods prefer light-curing adhesives for productivity reasons. This type of adhesive helps provide high positioning accuracy, as components can be initially fixed on demand. Once applied, the adhesive does not flow, which can happen when using heat-cured products in the oven.

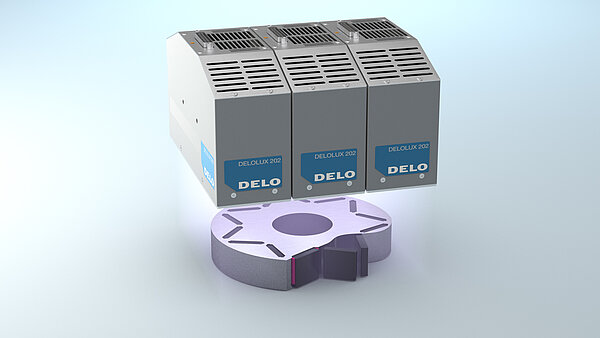

Light-cured adhesives achieve full strength within a couple of seconds when irradiated; in specials cases even less than a second. This is achieved with high-energy LED lamps that generate 100 to 1000 times the intensity of normal daylight within their specific light spectrum. The materials used in these systems are subject to limitations given maximum implementation temperatures of more than 150 °C and regular contact with aggressive chemicals, oil and acid.

Where there is light there is also shadow

When two components are bonded, it is important that all the adhesive is fully cured. If the light only reaches some of the adhesive, it will remain liquid in the shadowed areas. This exposes components to the risk of corrosion, or in the case of optical products, an undesirable effect on the light path. Shadowed areas should be avoided from the start of the design stage if light-cured adhesives are used.

The adhesives industry has developed many new dual-curing products for situations in which this is not possible or very difficult. Aside from light, they use a second curing mechanism so that adhesives can bond reliably, even in shadowed areas. This may either be humidity, air exclusion, heat or mixing resign and hardener. Each option fulfills different requirements and permits various manufacturing processes. All are products which are isocyanate- and silicone-free, with the exception of UV silicones.

Using natural humidity in the air

After initial fixation, light-/humidity-curing adhesives react with the natural humidity in the air in the shadowed areas. One benefit is that no additional equipment is necessary and no other curing process step is required after light curing. In addition, bonded components can be further processed immediately.

In chemical terms, light-/humidity-curing adhesives are closely related to conventional light-curing acrylates and possess similar properties. Due to the simplicity of the process, this product group is selected for medium requirements like maximum temperatures of use of 120-150 °C and moderate chemical impact. UV silicones work on the same principle and can even be used in temperatures of up to around 300 °C. However, due to their low strength, they are only suitable as sealants and also possess the typical disadvantages of silicones like swelling and contamination of production plant.

Light-anaerobic-curing adhesives

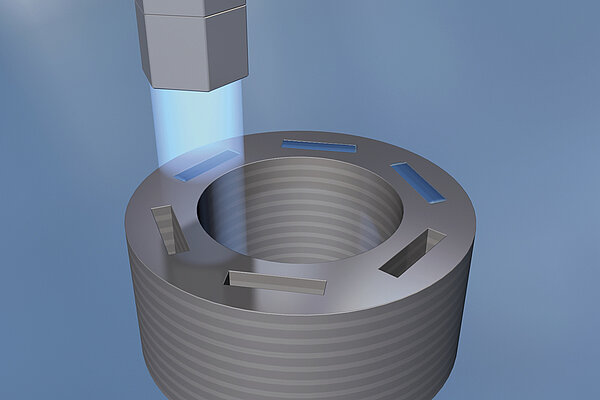

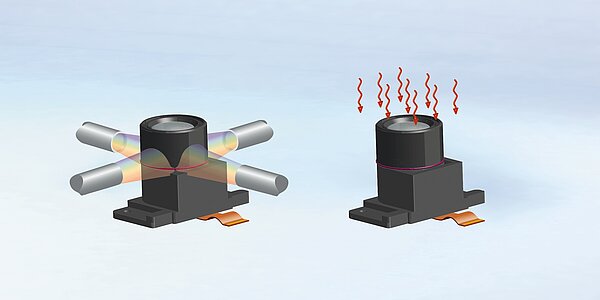

If requirements are higher, anaerobic curing, instead of humidity, is used as the second mechanism. Light-/anaerobic-curing adhesives offer high strength levels and temperature ranges up to 180 °C. They can be used for challenging applications in electric motors with high heat dissipation levels.

They are also resistant to chemicals in the automotive sector, like brake fluid, oil and road salt.

Light-/anaerobic-curing adhesives are based on the metal adhesives widely used in industry. Therefore, they need metal ions and oxygen exclusion to fully cure in shadowed areas. They offer two benefits compared to traditional methacrylate metal adhesives: On the one hand, productivity is higher due to fast light fixation, and on the other, the adhesive also cures on the fillet where otherwise air is frequently found. Both the purely light- and anaerobic-cured areas are well-cured and share similar properties. If sufficient metal ions are available, these products do not require a further process to cure in shadowed areas.

Full power: light + heat

The third option is light-/heat-curing materials, in which heat is applied to achieve full bond strength. This group is the most diverse. It offers products based on epoxy resins, acrylates and other chemicals, with the latter mainly used in optoelectronics thanks to its high transparency and low yellowing and outgassing.

Epoxides tend to display higher strengths. They are harder, and because of their denser network, resistant to chemicals and high temperatures. Some of these products are so resilient that they can be used in modules which are permanently in contact with hot transmission oil. Acrylates are softer and therefore more flexible and tension-equalizing, letting them better compensate dynamic stress.

An example of this is the attachment of decorative trims and cockpit elements in cars where component tension needs to be equalized in a temperature range of -40 -100 °C.

These product groups share a common feature in that they fix components with UV or visible light within a few seconds and thus ensure high production precision compared to standard products. Component shifting on the way to, or during, heat curing is avoided.

Convection ovens are usually used to supply the necessary heat for final curing. Alternatively, tunnel ovens, induction or thermodes can be used. Typical temperatures are around 100 °C, while the highest reliability products need at least 120 °C and temperature-sensitive components can be bonded with other materials at as little as 60 °C – so high precision, defined production processes and short cycle times can be combined with low thermal stress.

A revolution: light-fixation of two-component adhesives

Dual-curing epoxy resins are not necessarily one-component. For the first time, there is a viable and instantaneous form of light fixation for 2C epoxy resins in a matter of seconds. Their mechanical properties products are comparable to those of to 1C products.

After just a few seconds of irradiation, the components are sufficiently secured in their joined positions and protected against slipping so that processing of the entire assembly can go ahead immediately. The strength after an irradiation time of only 5 seconds at an intensity of 1000 mW/cm² already amounts to 1 N/mm², a value that is often defined in the industry as initial strength. Reliable final curing, including shadowed areas, is the same as it is for regular two-component products at room temperature.

A process at room temperature is likely more attractive to most users because it saves them from investing in an oven, eliminates energy costs for heat curing, as well as saves space on the production floor, while radically reducing cycle times and increasing throughput. Since dispensing, joining and light fixation take place in less than one minute, the next production step can begin much faster. Previously, this process commonly took 15 to 90 minutes.

> Free white paper download