The high-performance plastic PEEK is considered difficult to bond. This has been proven wrong through recent testing performed jointly by Evonik and DELO. Thanks to special epoxy resins, the bonded connections exhibit excellent strength even under demanding environmental conditions.

For many plastic processing companies, the bonding of high-temperature resistant materials such as polyether ether ketone (PEEK) is still a challenge. This is due to the low surface energy, the resulting poor wettability, and the chemical resistance of the plastic. In fact, however, Evonik and DELO have presented outstanding test results for PEEK bonding.

High Strength, Even Without Pretreatment

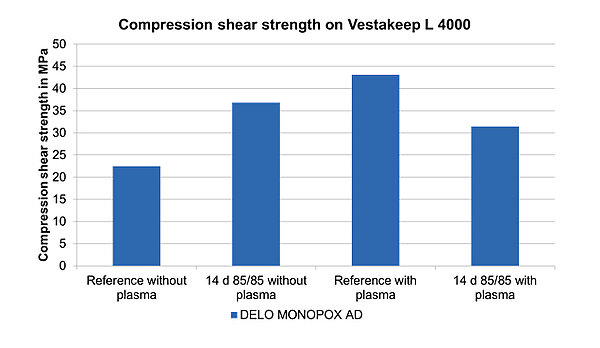

For example, the high-strength VESTAKEEP PEEK L4000G is very well suited for bonding with DELO MONOPOX one-component heat-curing adhesives. When bonding the PEEK parts compression shear strengths of up to 40 MPa were achieved, which is an extremely high value for plastics. To obtain these results, the components had been pretreated with atmospheric pressure plasma. The strength values remained high even under tough conditions of 14-day storage at 85 % air humidity and 85 °C.

In a further test using a DELO MONOPOX AD product that is particularly suitable for plastics, the PEEK bond showed good strength, even without atmospheric pressure plasma pretreatment, achieving values of about 20 MPa. Bonding without atmospheric pressure plasma pretreatment would significantly simplify the production process. However, particularly demanding applications may well require a pretreatment.

"Both PEEK and our epoxy resins are high-performance materials. The specimens were even deformed during compression shear testing, which shows the good quality of the bonded connection", says Karl Bitzer, Head of Product Management at DELO. "These results open the path to numerous new applications based on PEEK."

Not only in the aviation industry, for example in the field of modular components, but also in the automotive and mechanical engineering sectors, new opportunities are opening up: demanding sealing tasks can now be tackled with PEEK bonds.