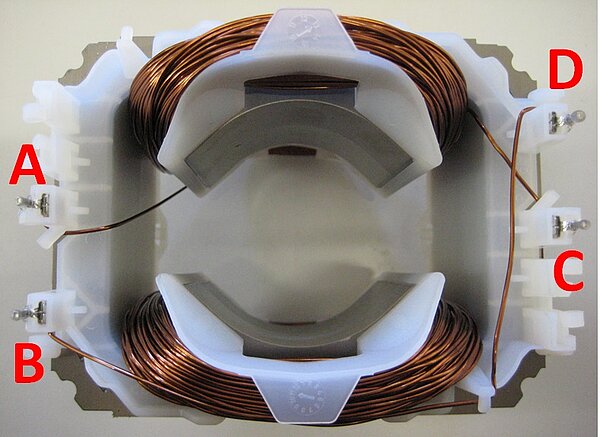

Miele, a family-owned and operated manufacturer of high-end household appliances, uses a dual-curing adhesive to seal tiny electrical contacts of its Mrt washing machine motors. This so-called crimp contact sealing prevents the ingress of humidity and protects the contacts from corrosion. Miele performs complex humidity and salt spray tests to ensure that the adhesive delivers its promised properties.

The Miele Group, based in Gütersloh, Germany, is one of the most renowned appliances manufacturers worldwide. According to the company, they employed a workforce of 19,400 employees in 2016/2017 and achieved a turnover of nearly 4.6 billion dollars.

For many years, Miele has been focusing on the manufacture of household appliances for kitchens, laundry and flooring, as well as equipment for use in commercial and medical facilities (“Miele Professional”). Miele’s products, in particular its washing machines, are well known for their durability. The company tests its appliances for a service life of 20 years, making it clear that any products installed or used in these appliances meet extremely high requirements.

Machines Need to Withstand Humidity

The purpose of sealing crimp contacts is to prevent contact corrosion of the aluminum-copper contacts. This is extremely important when it comes to washing machines that are being used where high air humidity is present, like in areas near the coast or on ships.

Crimp connections are mainly used in large-scale production, where single wires need to be assembled. Crimping is a fast method and a good alternative to soldering. It can help to create a connection to a conductor and connecting element that is barely detachable. With the help of tools, the cable and plug wires can be connected in a form-closed manner.

Protecting Contacts Permanently With Adhesives

In the case of Miele’s Mrt washing machine motor, sealing the crimp contacts is done using the one-component acrylate DELO DUALBOND AD4950. This adhesive offers high elongation at tear, and is able to equalize tensions, which is important for this type of application. It also features long-term stability that is a result of good aging resistance.

When validating the adhesive, Miele ran different tests to ensure that both the sealing and corrosion protection were high-quality. Simulating the lifetime of the adhesive bond, the components were sprayed with salt solution and exposed to different temperatures and humidity conditions for a given period of time.

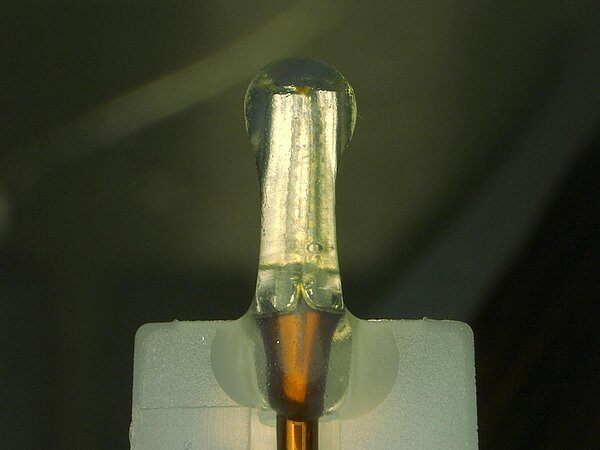

When cured, the product can be used at temperatures ranging from -40 °C to +120 °C. It also offers a dual-curing mechanism based on light and humidity. This means that after short exposure to LED irradiation, no additional process step is needed for final curing of the adhesive.

In shadowed areas, the ambient air humidity is sufficient for curing. This curing system is typically used for applications where the adhesive is transported by capillary forces into small shadowed areas and ensures that the liquid adhesive is fully cured in the final product.

Conclusion

In its assembly line, Miele uses a screw dispenser for fully automatic dispensing of the adhesive. Every step of the process is monitored by a camera system. This allows for control of the dispensing operation and detection of any bubble formations. In the subsequent curing step, the adhesive is shortly exposed to high-intensity light from an LED spot lamp. This lamp is the ideal when it comes to curing of very small adhesive drops or bonding areas within seconds.

Miele has successfully used this adhesive since 2013.