Automotive industry

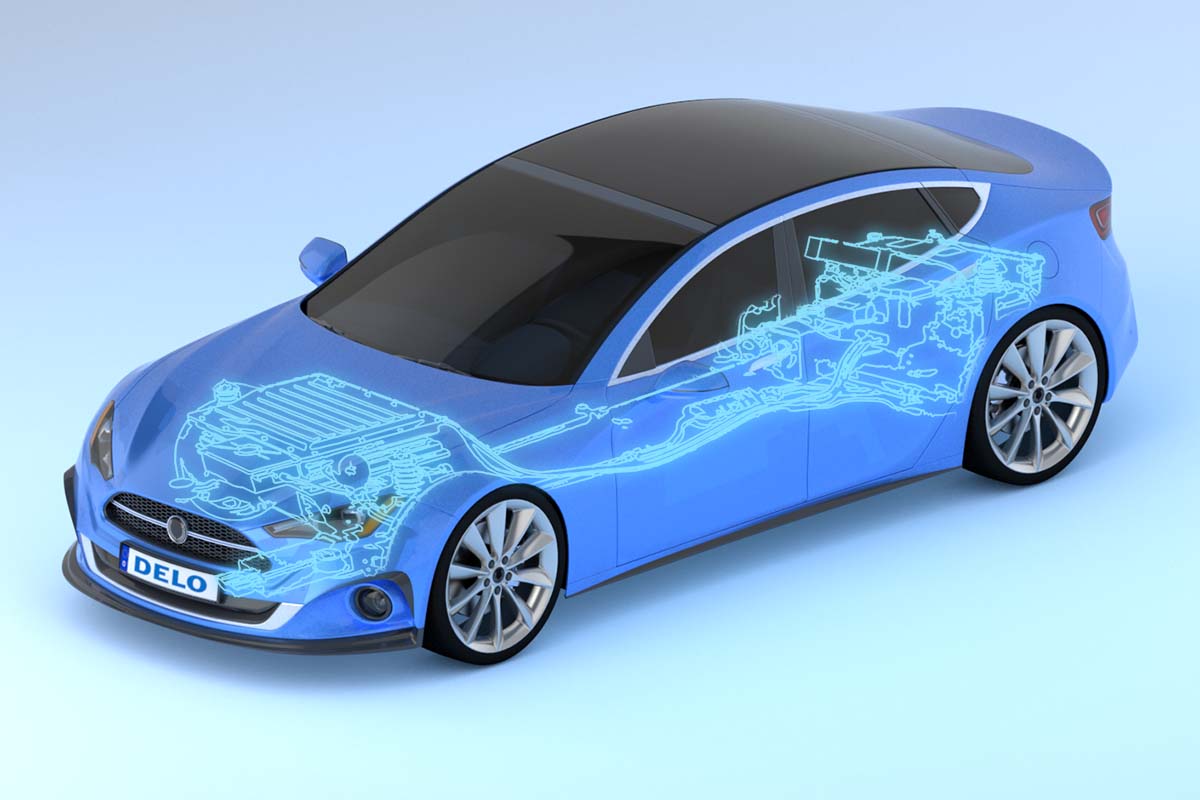

Innovative adhesives in automotive electronics and lightweight design: DELO ensures optimum adhesion

Cars and adhesives go together! Once an industry predominated by welding, soldering and screwing, car making is now embracing completely new joining techniques: today, for example, 15 kg of adhesives go into a car.

The advantages are obvious: Adhesives adhere to a wide variety of materials; they offer high elasticity, and can withstand major temperature fluctuations. Bonding is therefore a popular joining method, particularly in automotive electronics, where sensitive components such as camera and pressure sensors as well as fine contact wires in drive and control systems require reliable, permanent bonding. DELO adhesives, potting compounds and encapsulants, whose properties have been tailored exactly to the requirements of automotive electronics, are excellently suited for these tasks.

DELO adhesives for cars

The optimum product for every area

Brochures for download

A digital knowledge package

Adhesive bonding is a demanding joining technology. To successfully solve bonding challenges, you need a good understanding of the basics and special features of this technology. Build up valuable knowledge with the help of our "TECH TALK" webinars!

Quick Request

Do you have any questions?

Get in touch with us!

Technical consulting, sample and data sheet inquiries:

+49 8193 9900 - 9611

General & others:

+49 8193 9900 - 0