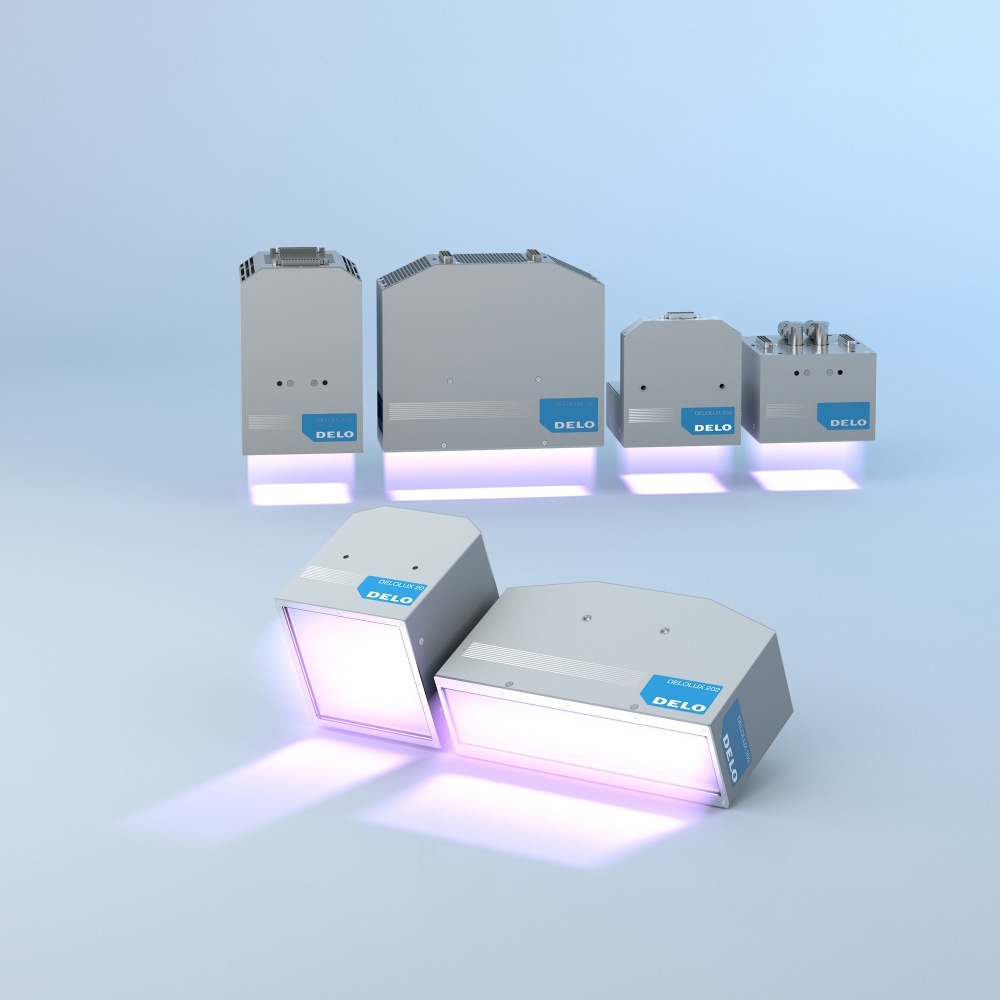

DELOLUX 20 | 202 | 203 | 204

High-intensity LED area lamps for large bonding areas

DELOLUX 20x series lamp heads are UV flood lamps. Distributing light homogeneously, a flood lamp enables curing of larger areas in a matter of seconds. Our LED flood lights can be adjusted to individual production settings and flexibly integrated into fully automated assembly lines. Different cooling mechanisms are also available for the lamps. Depending on requirements, you can choose between active air cooling, cleanroom-compatible water cooling and passive cooling.

They are especially suitable for large areas that need consistent illumination for curing: By placing DELOLUX 20 / DELOLUX 202 / DELOLUX 203 / DELOLUX 204 flood curing lamps in a row, it is possible to bring light evenly to large adhesion surfaces. In-series connection of these LED curing lamps is possible both on the x- and the y-axis.

Another advantage of these flood lamps: Thanks to the cold light source, heat development on the component is very low. In addition, this type of flood lamp shows a very long lifetime and completely even light intensity – for optimal curing results throughout their life cycle.

Benefits at a glance:

- Suitable for irradiating larger areas

- Ideal for fully automated production lines

- Cold light source – lowest heat development at the component

- Lifetime exceeding 20,000 hours

- Consistent light intensity throughout the flood lamp's lifetime

- Irradiation area can be expanded on the x- and y-axis

- Very even distribution of light even on large areas

- Same base unit for both types of lamp heads

- DELOLUX 20 and 202 - actively air-cooled lamphead (fan)

- DELOLUX 203 - passively cooled lamphead (preferably via water cooling profiles)

- DELOLUX 204 - integrated water cooling profile

Brochures of DELOLUX 20 | 202 | 203 | 204

THE FOLLOWING PRODUCTS COULD BE INTERESTING

Do you need assistance with your application?

Our experts will be pleased to offer advice and assistance.

Do you have questions about a specific application? If so, please use our project form.

The more detailed the description, the faster you will receive your optimum product sample.