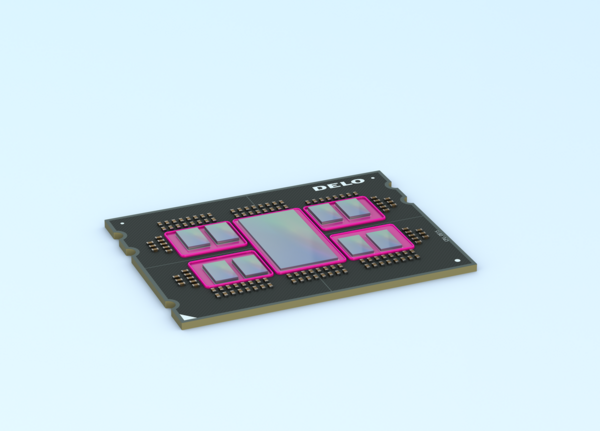

DELO has developed an adhesive that allows you to design ultra-fine structures in a matter of seconds. Our DELO DUALBOND EG4797 microelectronics adhesive opens up new possibilities for heterogeneous integration and optical packaging. Realize virtually any free-form structure and the finest optical barriers. The adhesive also takes into account the ongoing trend towards miniaturization.

New possibilities with the finest bond lines

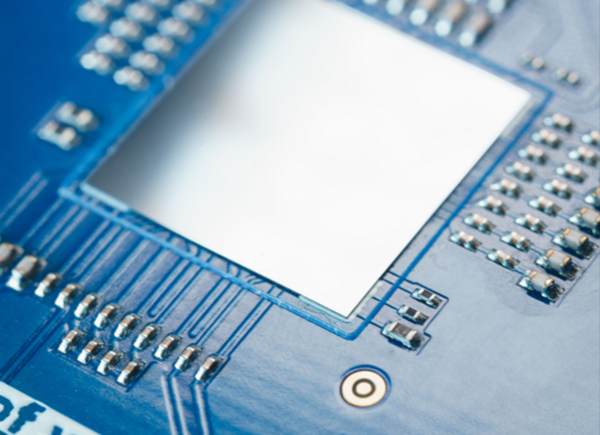

DELO DUALBOND EG4797 is a halogen- and solvent-free acrylate. It allows you to create the finest microstructures—so-called micro dams—in semiconductor packaging and on printed circuit boards. You can realize lines with widths of less than 100 µm in an aspect ratio of five or more. Previously, line widths of 200 µm were already considered a challenge. The new Micro-Dam solution was developed in close partnership with our partner NSW Automation, which produces the highest precision micro-dispensing technology for the semiconductor industry.

A special feature of the adhesive is its high thixotropic index of 6.6, which indicates the ratio of the viscosity of two different flow rates of an adhesive. As a result, DELO DUALBOND EG4797 can be dispensed at a speed of 15 mm/s and faster. This creates a stable microstructure layer by layer - on both straight and curved surfaces. The fine lines are dispensed with conical needles with a diameter of 100 µm.

Free choice of curing

After dispensing, the micro dam is cured in a single step and with low energy consumption, therefore enabling you to flexibly design your processes. You can cure either with UV light in ten seconds or with heat in five minutes at +120 °C. Another option is a dual curing process using UV light and heat.

Within typical testing standards (e.g. JEDEC MSL) for the microelectronics and semiconductor industry, DELO DUALBOND EG4797 shows very good results.

Advantages at a glance:

- High thixotropic index of 6.6

- Fast dispensing with more than 15mm/s

- Halogen- and solvent-free acrylate

- Dispensing of very fine lines with a diameter of 100µm

Microstructures with DELO adhesives

This adhesive comes as a response to increasing demand for high-performance components and simultaneous developments in miniaturization. More and more high-performance functional units are to be accommodated on PCBs.

Microstructures can, for example, serve as flow stops and reduce keep-out zones (KoZ). These areas are provided in the PCB layout to limit the flow of underfill adhesives for solder contacts and thus protect surrounding components. In the field of optical packaging, such as the manufacture of LED modules, micro dams act as ultra-fine optical barriers.

Thanks to these ultra-fine micro dams and their various processing options, you can realize almost limitless designs of free-form structures and completely new package layouts. At the same time, the amount of space required is reduced to a minimum.

Since its release, DELO DUALBOND EG4797 and the micro dam process have received much attention and many accolades. It was even awarded the 2024 Global SMT Global Technology Award for Semiconductor Packaging Adhesives.

DELO DUALBOND EG4797 and other adhesives for advanced packaging will be presented at various trade fairs. Visit us at our trade fairs and conferences to exchange ideas with our experts. Or do you already have a specific project for which you need our support? Take advantage of our free project consultation.